Analytical Balance Things To Know Before You Get This

Wiki Article

How Ohaus Analytical Balance can Save You Time, Stress, and Money.

Table of ContentsNot known Incorrect Statements About Gc Chromatography Analytical Laboratory for DummiesGetting The Analytical Laboratory To WorkEmsl Lab Things To Know Before You Buy

The scheduling problems with training can be overcomedigital sources are available anytime as well as anywhere the trainee has web accessibility. analytical balance. Below's the awesome part of application thoughin a case research that I have actually complied with, a colleagues of students then collect to educate each various other, based upon what they have learned online.It gets much better, the students are after that needed to use their wearable or mobile technology to tape the exact same operations during "daily" job over a collection period or number of occasions, and these video clips are then submitted for evaluation to make sure training transfer right into the workplace. This technique is development rather than revolution, but it has so much that is favorable going all out.

, then, with some standardization, we might maybe begin to construct an electronic educational program that could be utilized on a sector broad basis, which is the second vital proposition I desired to lead us in the direction of.

We may desire to ask ourselves if we are really providing a terrific industrial training and also learning experience to our personnel, and just how anything we do to improve the performance of lab training, could pay us pack extremely promptly in terms of enhanced compliance, high quality, as well as lab effectiveness. Not to discuss the spirits uplift in our staff that really feel more "purchased" and have the ability to proudly display their electronic badges which are accumulating well in the direction of their Registered Analytical Chemist accreditation.

Get This Report about Ohaus Analytical Balance

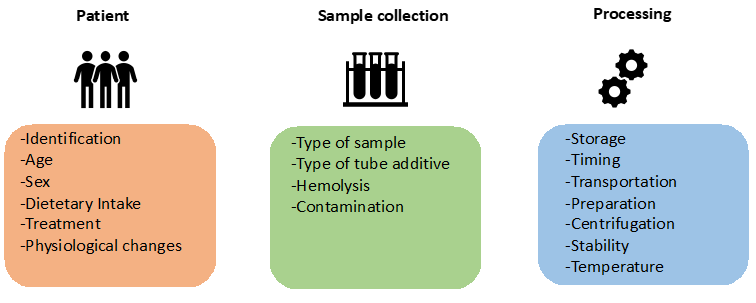

Pure as well as Applied Chemistry, 2016, Volume 88, Concern 5, pp. 477515; online 22 June 2016Human error in chemical evaluation is any kind of action or absence thereof that leads to exceeding the tolerances of the conditions needed for the normative work of the measuring/testing (chemical analytical) system with which the human communicates.On other actions of chemical analysis the human is the analyst/operator of the measuring system. The tolerances of the problems are, as an example, periods of temperature level and pressure values for example decomposition, pureness of reagents, p, H values for an analyte extraction as well as separation, etc. They are developed in a common operation treatment (SOP) of the analysis defining the normative work, based upon results of the logical method recognition study.

The errors might take place at any step of chemical analytical measurement/testing procedure, m = 1, 2,, M (location of the mistake). The primary steps, for instance, are: 1) option of the chemical logical technique and also matching SOP, 2) sampling, 3) analysis of an examination part, and 4) computation of test outcomes and coverage.

The chemical evaluation may begin from an analyte extraction from an examination section and also splitting up of the analyte from various other parts of the essence. On the other hand, finding of an analytical method and also SOP may not be needed in a laboratory where only one technique and also equivalent SOP are used for a particular task.

The Of Analytical Laboratory

The sort of human mistake and the step of the evaluation, have a peek here in which the error may take place, form the event circumstance, = 1, 2,, I. There are maximum I = K M scenarios of human mistakes. Because K = 9 right here, I = 9M. These circumstances created produce a map of human errors in chemical evaluation.The major system elements are: 1) recognition of the measurement/analytical method and also formulation of common procedure procedures (SOP); 2) training of experts and proficiency testing; 3) high quality control using analytical charts and/or various other ways; and also 4) supervision. Each of such parts has weak points, whereby mistakes are not avoided, comparable to holes in slices of celebrity.

That is received Fig. 1 as the pointers obstructed by the layers. In order for an event to occur as well as an atypical test result to show up, the holes in the layers must line up at the exact same time to permit a trajectory of occurrence possibility to pass the system (through its flaw), as portrayed in Fig.

Blocking human mistake according to scenario i by a quality system element j can be extra efficient in visibility of another component j' (j' j) as a result of the synergy (i)jj' between both components. The synergy might amount to 0 or 1 whenever the effect is missing or existing, specifically.

The smart Trick of Mettler Toledo Analytical Balance That Nobody is Talking About

The efficiency score of the high quality system at different steps of the analysis can be examined likewise. Instances of the metrology are available in Annex A of the Overview. Threat Assessment of Human Errors, Because the danger of human mistake is a combination of the chance and the extent of that error, their reduction rij is the risk reduction.

Report this wiki page